LED Christmas lights

One of the bummers of Christmas is trying to get the strings of lights

to work. The biggest culprit are the strings that are connected in series.

These are usually the strings of so-called miniature Christmas lights with

the push-in bulbs. You've probably read on the box that when one light

goes out the rest stay lit. True, the light bulbs have an internal

"shunting device" so that if one burns out, it doesn't break the circuit

and the rest of the lights do stay lit. But the problem is that if the

circuit should become broken at any other point, the whole string goes

out. The usual place this happens is between the lamp and the socket, especially

if the string is used outdoors. This is because water in the socket causes

the thin copper lamp wires to oxidize, which prevents them from conducting

electricity. Sometimes the wires on the lamp can become completely

eaten away. At any rate, it breaks the circuit and the string doesn't work.

Finding the broken connection is no easy matter, especially when you

consider that most strings have at least 35 lamps. I've seen every trick

in the book used to get a bad string to work, using an ohmmeter to find

the bad connection, even running a high voltage through the string which

causes an arch to form at the point of the broken connection. To make matters

worse, there's usually more than one broken connection. Whatever method

is used can be time consuming. You may be wondering, if series strings

are such a hassle, why don't they run the lamps in parallel, like they

do with the strings that use 120 volt light bulbs.

Many of you are probably not old enough to remember the so-called transformer

light strings of the 50's. They were usually strings of low voltage blinking

lights that had to be run in parallel, because when each light blinked,

it would break the circuit. The transformer was about the size of

the type that ran model electric trains (probably made by the same transformer

company), except it was a fixed voltage (I think 6 volts) and was probably

about 10 amps. When lamps are in parallel, the current adds up, so it took

a pretty hefty transformer to run the lamps, which added to the cost of

the string. Because of the high current, the wire size of the string also

had to be a heaver gauge. This is probably the main reason they don't make

these strings anymore. The miniature strings of lights could be made with

24AWG wire and no transformer.

Enter the light emitting diode. Although they've been around since the

late sixties, it has only been in recent years that they have become suitable

for Christmas light strings. The first problem was the lack of colors, red was

all you could get. By the mid-70s, you could get three colors, red, yellow and

green, but the color shades weren't that great and lack of briteness was another

problem.

By the 1990s, all these problems had been eliminated, and LEDs looked as good

as miniature Christmas lights, and also had a lot of advantages. They use about a tenth of the current of normal

miniature Christmas light bulbs, they have a life of 100,000 hours, they

have much thicker wires than miniature Christmas light bulbs and they now

come in all the colors of the rainbow and are much brighter than LEDs were

only a few years ago, and you can even buy LEDs that blink.

Here's the two lamps in a side by side comparison, the lamp on the left

is a conventional miniature Christmas light. Between the two wire supports is the filament that gives off the light. The lamp

on the right is the light emitting diode. It is made out of plastic instead

of glass and it is not hollow. That makes them virtually unbreakable. The

metal substrate holds the semiconductor material that gives off the light.

They generate very little heat. Both lamps are mounted in the plugs that

fit the miniature Christmas lamp sockets. Unlike regular incandescent lamps,

LEDs don't have to be colored to produce colored light. It's the semiconductor

material that determines the color of the lamp. Since making this material

produce more than a narrow wavelength of light is difficult, white LEDs

are produced to generate ultraviolet light, which causes a phosphor coating

to glow, much like a fluorescent lamp, only without any poisonous mercury.

the two wire supports is the filament that gives off the light. The lamp

on the right is the light emitting diode. It is made out of plastic instead

of glass and it is not hollow. That makes them virtually unbreakable. The

metal substrate holds the semiconductor material that gives off the light.

They generate very little heat. Both lamps are mounted in the plugs that

fit the miniature Christmas lamp sockets. Unlike regular incandescent lamps,

LEDs don't have to be colored to produce colored light. It's the semiconductor

material that determines the color of the lamp. Since making this material

produce more than a narrow wavelength of light is difficult, white LEDs

are produced to generate ultraviolet light, which causes a phosphor coating

to glow, much like a fluorescent lamp, only without any poisonous mercury.

Converting an old miniature light string to work with LEDs is fairly

easy for anyone who knows how to soldier. It is also a good project to

learn how to soldier for those who don't, but you should practice on scrap

wire first, before trying to build the string. It involves cutting a series

string apart and rewiring it in parallel, with a series resistor for each

of the LEDs, which limits the current of each LED to 20ma. This usually

works out to be 470 ohms for a 12 volt power supply. Below are the

power supply requirements according to the numbers of LEDs in the string for a

LED current of 20 mA.

| LEDs in string |

Power supply current: |

| 10 |

200 mA |

| 20 |

400 mA |

| 25 |

500 mA |

| 30 |

600 mA |

| 40 |

800 mA |

| 50 |

1 A |

| 100 |

2 A |

I begin by cutting the light sockets off the string about three inches

from the socket and I store them in a box. There is usually a wire that

goes from one end of the string to the other (two such wires if you're

lucky to have a string that has an electrical socket at the end of the

string), which I wind onto a spool. Sometimes you can find wire the right

shade of green wire at electronics stores. I find that 22AWG size stranded

wire (make sure it is not solid) works the best. Also get some 1/8th inch

heat shrink tubing to insulate your connections. It usually comes in four

foot lengths. It may take two of these lengths to do an entire string.

You will also need a heat source to shrink the tubing. If you don't have

a heat gun, a lighter can be used if you are careful.

After you get the string cut apart, you should strip about a half-inch

of insulation off the socket wires and soldier a 470 ohm resistor to one

of the two wires. It should look like this. The color code for a 470 ohm

resistor is Yellow,

Violet,

Brown.

To build the string, I cut the green wire into 7 inch lengths. When

soldiered, that gives about a 6 inch spacing between sockets, close to

that of the original string. When the 7 inch wires are attached, it looks

like this:

Two of the four wires go to the previous lamp in the string (or to the

power supply if it's the first lamp in the string) and the other two wires

go to the next lamp in the string. Since LEDs are polarized, (electrons

will only flow through them in one direction because they're diodes) you

should wire the string so that all the resistors are in the same line (I

choose +). That makes things easier when plugging the LEDs into the string.

Although LEDs can operate on AC, I have misgivings in doing so and prefer

to operate them on filtered DC. For one thing, it protects the LEDs from

power surges, because the filter capacitors in the power supply tend to

filter out any spikes on the AC line.

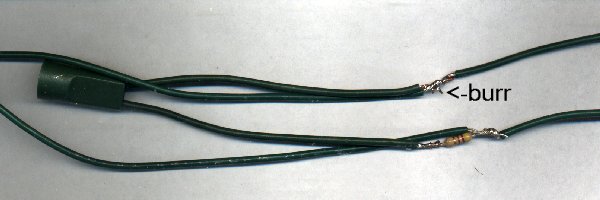

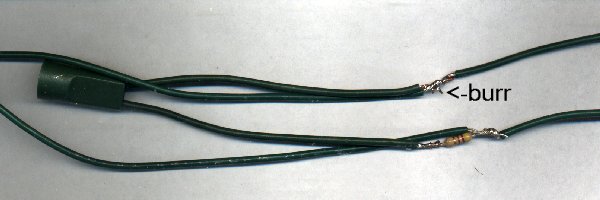

The next step is to cover the connections with heat shrink tubing and

to shrink it with your heat source. Before you do this, you should smooth

out any sharp burrs (such as can be seen on the top wire above) in the

connections with needle nose pliers. Otherwise they could poke through

the heat shrink tubing. This wiring process is repeated for each lamp socket

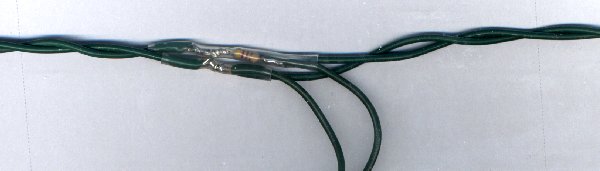

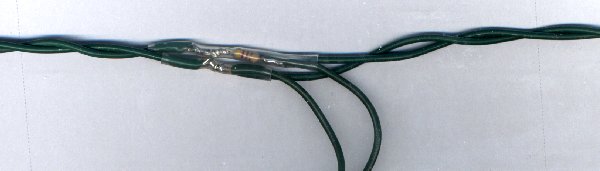

in the string. Now for a look at the finished connection:

Notice how much nicer the connections are than if you were to cover

them with electrical tape. You don't have to worry about the tape peeling

off. The heat shrink tubing is there to stay. After shrinking the tubing

over the connection, the two wires between the sockets is twisted together

just like is done with a normal string of Christmas lights.

Now it's starting to look like a light string. The two wires heading

down go to the light socket (not shown).

Neon light strings

You can also construct line voltage strings that will work with neon

indicator lamps, often known as NE-2. Like the miniature Christmas lights,

these lamps have wire leads and fit the same sockets. The only change you

have to make in the string construction is to use 100k series resistors

rather than the 470 ohm ones required for LEDs. Also, you can get green

"neon" lamps the same size of the orange ones. These are actually argon

glow lamps with a fluorescent coating that glows green from the ultraviolet

light that the argon discharge produces. You used to be able to get the

argon lamps without the fluorescent coating, but I don't think they make

them anymore. These argon lamps may need a different resistor value than

the neons.

Light chaser strings

Instead of having two wires, these strings have five, one for each circuit

and a common return wire. I refer to this common wire as the backbone of

the string, since it is the only wire that connects to every socket. One wire from each socket connects to the return

wire through the resistor, and the other socket wire connects to one of

the four circuit wires, the first socket in the string to circuit 1, the next to

circuit 2, and so on. I use 5-pin DIN connectors to connect the string to the

chase controller.

[return to the electronics index]

Copyright © 2002, Colin Pringle (colin@wild-bohemian.com)

The mail link automatically fills in the subject field so I will know

which page you're commenting on.

All rights reserved

electronics/led_lights.htm

the two wire supports is the filament that gives off the light. The lamp

on the right is the light emitting diode. It is made out of plastic instead

of glass and it is not hollow. That makes them virtually unbreakable. The

metal substrate holds the semiconductor material that gives off the light.

They generate very little heat. Both lamps are mounted in the plugs that

fit the miniature Christmas lamp sockets. Unlike regular incandescent lamps,

LEDs don't have to be colored to produce colored light. It's the semiconductor

material that determines the color of the lamp. Since making this material

produce more than a narrow wavelength of light is difficult, white LEDs

are produced to generate ultraviolet light, which causes a phosphor coating

to glow, much like a fluorescent lamp, only without any poisonous mercury.

the two wire supports is the filament that gives off the light. The lamp

on the right is the light emitting diode. It is made out of plastic instead

of glass and it is not hollow. That makes them virtually unbreakable. The

metal substrate holds the semiconductor material that gives off the light.

They generate very little heat. Both lamps are mounted in the plugs that

fit the miniature Christmas lamp sockets. Unlike regular incandescent lamps,

LEDs don't have to be colored to produce colored light. It's the semiconductor

material that determines the color of the lamp. Since making this material

produce more than a narrow wavelength of light is difficult, white LEDs

are produced to generate ultraviolet light, which causes a phosphor coating

to glow, much like a fluorescent lamp, only without any poisonous mercury.